The Patent Office

by Elton Gish

Reprinted from "Crown Jewels of the Wire", August 1988, page 15

THE NATIONAL SELF-BINDING INSULATOR

CD 110.5 and CD 110.6

The National Screw-Top insulator is found in two styles namely CD 110.5 and

CD 110.6 as shown in the photos below. Both styles are rim embossed with four

patent dates with the last date pertaining to two similar patents:

May 1, 1883

|

#276,839 by Joseph S. Lewis

|

Dec.25, 1883

|

#290,922 by Frank L. Pope

|

Jan. 1, 1884

|

#291,072 by Edward J. Murphy

|

Oct. 7, 1884

|

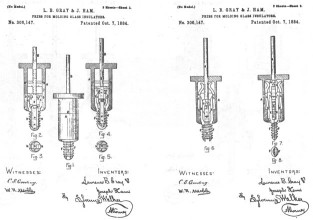

#306,146 by Lawrence Gray

|

Oct. 7, 1884

|

#306,147 by Lawrence Gray/Joseph Ham

|

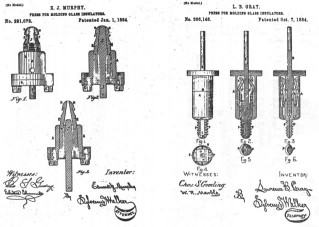

The later three patents deal with a new method of forming threads in glass

insulators and are very prominently signed by the sane patent attorney, Sylvenus

Walker. The Murphy patent was assigned to Gray and Ham which may explain why

they used the same attorney and a common witness, Charles Gooding. The first two

patents are very interesting in that they have almost identical claims and Frank

Pope was the patent attorney for the Lewis patent. For brevity, only the patent

drawings are reproduced and they follow this article.

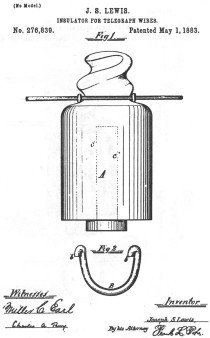

Joseph S. Lewis was from England and he obtained the patent No. 276,839

dated May 1, 1883. The Lewis patent claims were for a conical or expanding

screw-thread on the exterior to accept a new design of tie wire consisting of a

horseshoe form of rigid metal clip provided with open hooks for the purpose of gripping the

line wire (refer to the drawing of the Lewis patent). The insulator employing this

design was threadless.

Threadless insulators were popular in England and were the norm as most of the insulators used

there were

preferably cemented to the pin.

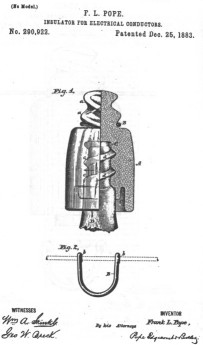

Frank L. Pope was Mr. Lewis' patent attorney as can be seen by his signature

on the Lewis patent. The Pope patent is No. 290,922 and dated December 25, 1883.

Mr. Pope evidently was quick to recognize that the Lewis patent had a few short

comings if it were to be used in the U. S. and his filing date of May 23, 1883

employing those improvements was just 23 days after the Lewis patent was

awarded. Mr. Pope used a similar drawing for his patent filing as well as text

that was word for word in many areas. His patent was designed for a threaded

insulator so the insulator could be screwed onto the pin and, with the opposing

threaded top (opposite twist to the Lewis patent), the tie wire could be secured

at the same time! Eureka! A better "mousetrap"! In all fairness, the

pitch of the screw top on the Lewis patent was totally satisfactory for

threadless insulators.

It may be appropriate here to mention some background about Mr. Pope. He was

a very prominent man in the field of telegraphy, electrical engineering and

patent law. He was first associated with electrical work when he was appointed a

telegraph operator on the American Telegraph line in 1857. A few years later, he

was a draftsman in the Patent Bureau of the office of the Scientific American

where he acquired much knowledge of patent law. In the war of the Rebellion

(Civil War), he reentered telegraph service in 1861 at Providence, RI where he

attracted the attention of Marshall Lefferts of the American Telegraph Co. who

later commissioned him to make a complete, detailed report on the company's

lines covering thousands of miles from Maine to Virginia (a two year job).

He held several patents on the construction of printing telegraphs and

electric railway signaling apparatus. He was responsible for convincing Mr.

Westinghouse of the benefits of electric power using alternating current. He

aided in the publication of the weekly trade journal "The Electrical

Engineer" and was the second president of the AIEE in 1886. Mr. Pope was

very influential and very possibly, due to his reputation, had much to do with

the success of the National Self-Binding insulator.

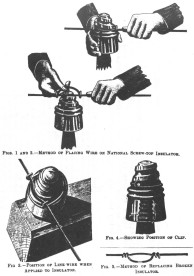

The Electrical Review article dated August 29, 1885 reprinted on the

following pages, publicly introduced the National Self-Binding insulator.

Illustrations 1 and 2 correctly show the insulator with reverse external threads

as detailed in the Pope patent. However, in illustrations 3 and 4, the engraver,

apparently confused , showed the external threads with the opposite twist as detailed in the Lewis patent!

|

This article is reprinted from the August 29, 1885 issue of the Electrical

Review.

The National Self-Binding Insulator.

This insulator, which is coming into

particular favor with telephone and telegraph people, is now controlled in the United States by

Messrs. Lytle & Co., of this City. The American Bell

Telephone Company have decided to adopt them for their long line work, and other

local companies are using them with very satisfactory results. This Insulator is

the invention of J. Slater Lewis, of England. and is being extensively used in

Europe. It dispenses entirety with the old and troublesome tie-wire, being so

constructed that the line-wire is applied and secured without the use of any

tools whatever, and in the shortest possible time. It can be used in any situation, whether on curves,

against walls, under bridges. on roofs or wherever

a tie-wire can he used. It is remarkably simple, durable and efficient, and may

be removed or renewed with the greatest facility. It is constructed with a

conical and expanding screw-thread upon the exterior of the upper portion,

similar in form and principle to the point of a gimlet.

The line-wire is

attached by means of a rigid wire shackle or clip, formed is the shape of a

horseshoe. the curved portion of which is adapted to encircle the body of the insulator

at the base of the conical screw portion, while each end of the clip is

made into a hook adapted to grasp the line-wire. The bell of the insulator below the point of

support of the line is given the form shown by experience to be the best.

Besides the peculiar form of attachment for the wire, the National

Insulator is provided with a perfect internal screw. It is formed by newly-invented molding

tools of peculiar form; the greater sharpness and accuracy of the thread gives a

better hold to the pin, and facilitates the operation of securing the

insulator both to the main line and to the support.

The figures 1 and 2 show the

position of the clip and line-wire when applied to the insulator.

The insulator

having been screwed on the bracket or pin, give it three complete turns backwards after it has come to

its bearing, and hook the clip on the line wire

with the ends of the hooks turned upwards, as shown In Fig. 3, then drop the clip and line wire over the top of the insulator as shown In the

same figure,

after which the insulator must be screwed down on the pin as shown in Fig. 4.

Care must be taken to see that the clip goes down the thread of the screw first

with the line wire following it, the screwing motion being continued until the insulator comes to its bearing on the pin or bracket, when the attachment will

be complete.

It will be seen that the insulator is secured

to the pin or bracket, as well as to the line wire, by a single

operation. In detaching the line wire this process is exactly reversed, the

insulator is turned the other way, the line wire going up by the groove first and

the clip following. Some linemen prefer to carry a pocket oil can, and before

screwing on the clip they apply a single drop to the point oh the clip, and also

on the line wire which rubs against the Insulator; friction is thereby avoided

and the work made easier.

To replace a broken or damaged insulator of the common

kind, it must be smashed and the pieces taken out. leaving the tie-wire attached

to the line as shown in Fig. 5. The new insulator is then screwed on the pin or

bracket as before, and the loop placed over the top of it, after which the

operation is precisely the same as illustrated in Figs. 3 and 4. After a little

practice the attachment may be made with great rapidity. |

Medium Image (47 Kb)

Large Image (147 Kb) |

Another interesting article, reprinted below, is from the Electrical Review

date January 17, 1885 where it states that the tools to make the new

"Lewis" insulator were about ready. No mention of the "Pope"

insulator. Note that the manufacturing facility was in Haverhill, Mass.

|

- - - - - - - - - - -

-

In Mr. Duxbury's office I met Mr. Lytle, who was down from

Boston on business. He tells me that work on the new insulators at Haverhill

is

progressing favorably; that the tools for making the new English (Lewis) "screw

top" insulators are about ready, ant that they expect to turn out a big lot

soon. By the way, a funny thing. Insulators is England are made of earthenware,

glazed. They "come high" over there -- not far from sixteen cents each.

They are made in a lathe, fired, then glazed, then fired again and are such

handsome pieces of pottery that one wonders they are not put up in velvet-lined

cases like Sevres cups. Why are they made of earthenware? Because in England, you

know, we always use iron pins -- not the wooden things you stick up in this country,

don't you see? Now, if we put on glass, the sun shines through it and don't heat

it. but it does heat the iron, you know, expands it, and cracks the

glass.

But if we use earthenware; don't you see, the sun can't do it. you know. Poor

things, it never occurred to them to use opague glass; simply because they

never had used opaque glass; but I am of the opinion that when Mr. Lytle

gets over there with a few thousand screw-top insulators, made in one motion with a

perfect inside thread, and of a beautiful white glass that the sun can't shine

through, any more than it can through a piece of iron, and offers them at less

than one-half what it costs the manufacturers over there to turn out their hand-made

ceramic specimens, the folks will wake up to the idea that "those

blasted Yankees'.' still have an idea or two that they have not as yet had any conception

of. By the way, Mr. Duxbury tells me that he has tried some of the new insulators

of the "pony" size, and likes them very much indeed.

- - - - - - - - - - |

The National Insulator Co. referred to it as the Lewis insulator even though

the Pope patent was the one used for the final design -- internal threads,

opposite twist to the external thread and horseshoe form of metal clip. An

apparent close association with the company by Mr. Lewis may be why the

insulator carried his name.

Medium Image (52 Kb)

Large Image (139 Kb)

Medium Image (50 Kb)

Large Image (140 Kb)

Medium Image (74 Kb)

Large Image (201 Kb)

Medium Image (57 Kb)

Large Image (154 Kb)

|